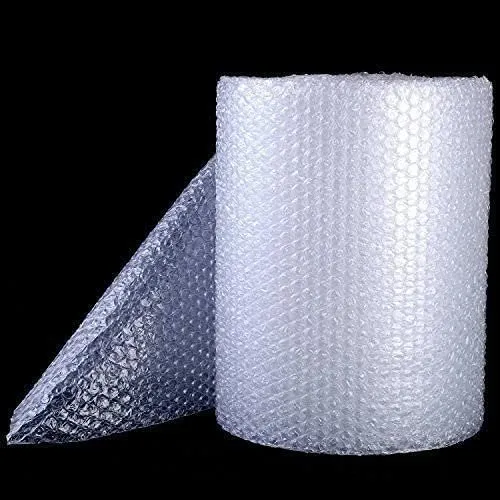

Bubble sheets, commonly known as bubble wrap, hold a prominent position within the realm of industrial suppliers, offering a versatile and protective packaging solution. Comprising a sheet of plastic with regularly spaced air-filled bubbles, bubble sheets have become synonymous with safeguarding delicate and fragile items during transit, storage, and handling.One of the primary functions of bubble sheets in the industrial supply chain is to provide a cushioning barrier that shields goods from impacts, vibrations, and shocks. The air-filled bubbles act as a resilient layer that absorbs and disperses external forces, preventing damage to sensitive items such as electronics, glassware, and delicate machinery. This protective quality is especially critical in industries where the integrity of products must be maintained throughout the entire logistics process.

Industrial suppliers value bubble sheets for their adaptability to various shapes and sizes. The flexibility of bubble wrap allows it to conform to the contours of irregularly shaped items, ensuring complete coverage and protection. This versatility makes bubble sheets suitable for a wide range of products, from small and delicate components to larger, more robust items, offering a universal packaging solution that caters to diverse industrial needs.

Connect with Us

Bubble sheets are considered a cost-effective packaging solution due to their lightweight nature and ease of use. They add minimal weight to packaged goods, contributing to reduced shipping costs. Additionally, the simplicity of incorporating bubble wrap into packaging processes, whether manually or through automated systems, makes it an efficient and time-saving option for industrial suppliers seeking streamlined logistics operations.